A question that we are often asked is, does a snowmobile have a clutch and if it does how do I work one? There is nothing to be worried about, and by the end of this article, you will be an expert on the subject. So let’s see how do snowmobile clutches work.

All snowmobiles have a clutch; you don’t have to worry about a stick shift though. Your snowmobiles clutch is a form of continuously variable transmission (CVT), think about like an automatic car. You only need to use your throttle and brake.

It takes two, baby

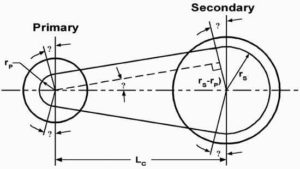

Two pulleys control the CVT system, these pulleys are your clutch. These pulleys sit on the engine crankshaft and your track drive respectively. They are connected to each other by your drive belt.

The pulley sitting on the engine crankshaft is your primary clutch. This pulley is held apart by a pulley spring when you are riding at low RPMs. Now as you start to gun it, the RPMs will increase. The increase in RPMs generates a centrifugal force through your primary pulley, and this closes it. As it closes your drive belt finds it easier to move, and this increases the power.

Your secondary clutch is on the track drive. In this pulley we have little wedges called cams, another spring controls these cams. As you start to twist your throttle these cams begin to get tightened, the higher the RPM, the tighter they get. As the cams squeeze together your belt is tightened.

This closing and squeezing of the pulleys will continue until you are going as fast as your sled can go. Top speed is marked by the point that your primary clutch is closed.

To infinity and beyond

Now think back to our automatic car. How many gears does your car have? Five, six? Well, the CVT system means that your snowmobile has an infinite number of gears. The infinite range of gears is because the CVT system is stepless. It just moves up and down, at each speed you stop accelerating or decelerating at you are in the correct gear for that speed. It is almost like magic.

that your snowmobile has an infinite number of gears. The infinite range of gears is because the CVT system is stepless. It just moves up and down, at each speed you stop accelerating or decelerating at you are in the correct gear for that speed. It is almost like magic.

You will now also see that some manufacturers are starting to create a Hi/Lo gear options, some such as Arctic Cat are extending this to three speeds. To switch between these settings you will find a Hi-Lo shifter on your sled. This function allows your snowmobile to have a lower and higher running speed.

Example

In the video below, you can see the Polaris XC 600 SP CVT clutch in action. You can clearly see the shift ratio variation when the engine revs up and down during dyno test.

The history of the CVT

Would you like to know a little something to amaze your friends? When do you think this infinite position stepless clutch was designed? 1980? 1960? 1900? All wrong. Possibly the greatest mind of all time drew the design for a CVT system in 1490, yes we are talking of Leonardo DaVinci, not the turtle but the artist.

The first patent for a CVT system was filed in 1886. As you can see the CVT idea has been about for a while. It took until 1950 for CVT to feature on a snowmobile. It came on the Eliason K-10, a sled that could trace its origins back 1927 when Eliason patented the first snowmobile.

It is all going backward

We have talked about going forward but what if you need to back your sled up? Thankfully at the end of the 1990’s some engineers created the Rotax Electronic Reverse (RER). RER allowed you to go backward at the touch of a button. It was also a pretty light system.

Before that mechanical reverse systems were heavy, so most snowmobiles did without one. Saved you burning through fuel and having the added complexity when it came time to fix your sled. The simplicity of the RER switch is that it slows the engine down, it comes to a stop, starts back up, but this time it is in reverse. No magic or fairy dust needed, just some clever engineering.

There are still sleds without reverse and some with mechanical shifting, but they are becoming a dying breed. You probably want to keep on eye on your friends when you have an electronic reverse button on your snowmobile, particularly if they are like these Swedish guys.

Put it in neutral

We’ve talked about going forward and going backward, so what about neutral? Again some sleds have neutral, and some sleds do not have neutral. You will also find some people who tell you when it is way below zero to put your snowmobile in neutral and then rev it. You should ignore these people as they obviously have shares in spare parts companies. Do not do this and destroy your engine. You can usually find your neutral position on a lever; this varies by manufacturer so please check by brand.

So we get that we have an infinite number of gears, which means we need to make sure that we keep our snowmobile’s clutches in perfect running order. We do this by scouring our clutch sheaves and making sure the drive belt is tensioned. If this sounds scary read on and it will seem a lot easier, as with all mechanical tips the more you work on your snowmobile, the easier the tasks will become.

Keep your clutch clean and tidy

A great time to work on your clutch is if you are fitting a new belt. Look at your clutch sheaves, check your manufacturer’s schematics if you are unsure where to find them. Now grab a piece of 150 grit emery cloth. Rub the cloth from the center of your clutch out to the outside edge. Make sure that you cover every part of the clutch and remove all and any glaze from your clutch.

Grab your new belt and look at your clutches. Hopefully, they will be scoured and not shiny and polished. You do not use steel wool; it will polish your clutch, always use a rough piece of emery cloth. Pop your belt on and adjust to the manufacturer’s guidelines, it should be in that book where you found where your clutch pulleys are.

Too loose with your belt and your snowmobile will lose its low-end power. Too tight and it will squeal like a pig at you. Get your tension right and enjoy a great winter of sledding.

You ain’t finished yet though. You’ll need to wash and clean your clutch pulleys. If you don’t do this, then the metal dust you just created will get into your clutch’s bearings and rollers. If this happens, you will start the rush towards big spare parts bills.

The simplest way to remove this dust is just to rinse the area with warm water. You could use brake cleaner, but you will need to make sure and go over everything with a cloth afterward. You also do not want to shortcut this cleaning process by using compressed air; this will just help to blow the dust into all the areas you were trying to remove it from landing in.

Other Snowmobile Clutch Maintenance

There are more maintenance tips that we should talk about, but I will cover this in another article. It’s too long for this article.

Snowmobile Clutch

How often does it break?

The usual snowmobile clutches last between 1200-2000 in my experience. There are several factors that influence this number. From the quality of the clutch, installation process, maintenance, environment to how you ride the sled.

Price

It’s definitely one of the most expensive parts of a snowmobile. A new clutch can vary from $200 to $350 (with some exceptions). I recommend getting a new one because the installation will take some time. It’s not worth paying the money and then to have to change it again soon. A new clutch will last a lot of miles: 1200-1500-2000 miles. It obviously depends on how you ride the snowmobile and other environmental factors.

Replace the sled’s clutch?

Here is a little step by step tutorial on how to change the primary clutch on a 1997 MXZ. The rules are pretty much the same for all types of sleds. But the details can be different. Use your intuition or let a professional do the thing.

You can find the new clutch easily on eBay. Make sure it fits your sled’s model and you are good to go. Also, this is a good moment to replace the belt if it’s old or cracked. If you don’t change the belt with a new one you should set your deflection. The tools needed for this operations can be easily found on Amazon. I will put a link for each one.

Basic steps to replace it:

1. Remove the clutch cover (it covers both clutches)

– It’s a pretty easy operation as you can see. Usually, there are two tabs that are holding the cover.

– Now you have the belt exposed

2. Next, remove the belt

– The snowmobile usually comes with a tool that fits the belt screw. Use this little tool to unscrew the secondary clutch.

– After you complete the operation the secondary clutch should split apart.

!Easy way: if your belt is loose enough, you can try to pull it out over the clutch without splitting apart the clutch

3. Move to the primary clutch: if there is a cover over the clutch bolt you need to take it out.

Next, remove the bolt. You will need a key to do this, also you will need to find a way to hold the clutch in place. If your sled’s toolkit has this tool, use it. If not, use a wrench or other tool to hold the clutch in place.

4. Use a clutch puller to pop the clutch off the crankshaft.

5. Use a monkey wrench to pop it out

6. Get your replacement clutch and put it in place. Slip it back on in the same position as the old one.

Time to reverse the process:

7. Put back the primary clutch bolt that you took off. You can even buy a new one if you want. But most of the time, this is not needed.

You need to use a torque to torque down the bolt. About 70 foot-pounds should be enough for final screwing. But start lower (about 50 foot-pounds) and then move to 70 foot-pounds. This way it’s easier.

8. If you want to change the belt with a new one, this may be the time. If the old one is not cracked and in good shape, you can use it. Put it in in the same position as the old one.

If your belt is not that loose, you still need to split apart the secondary clutch.

9. Put back the cover

Note that this guide does not apply to all models, you will need to use some common sense and your mechanic skills. If you don’t have any, you will be better of calling a mechanic or go straight to a snowmobile repair shop.

Tools you will need and link to Amazon:

- The new clutch (Actually, you can find this one on eBay) – make sure it fits your sleds model

- The new belt (only if the old one can not be used anymore, look for cracks, you can find one on eBay)

- Tool to remove the belt (you should already have this in your sled’s toolkit) – Or take it out without splitting apart the secondary clutch

- Socket Set and Breaker bar – these tools are handy (Link to Amazon)

- Tool to hold the clutch in place or wrench (Link to Amazon)

- Primary clutch puller:

Polaris Ranger/RZR: 1999 2000 2001 2002 2003 2011 2012 2013 2014 2015 2016 2017 2872085 2875567 8000-4005 (Link to Amazon)

If you can’t find your model, try the universal kit: Link to Amazon – You can check if it fits your model - Adjustable Torque Wrench (Link to Amazon)

The end is near

Congratulations you are now an expert on the CVT system and the infinite number of snowmobile gears. Give yourself a big pat on the back, and after all, it was not as daunting as you thought it was going to be now, was it?

Also, you have the basic mechanical knowledge and if you are good with tools, you can change your sled’s clutch and belt on your own.

If you have anything to add or any questions about your sled’s clutch feel free to comment in the section below. I will try to respond asap and help you find the answer to your need.